- my new view sitting at the torch…

I’ve been waffling for the past year or so regarding whether or not i really wanted to upgrade my torch – it’s expensive and meant I would have to invest in additional equipment and a proper ventilation system. Then, a couple days before the November bead show

the glass gods made that decision for me: my Hothead died! So, at the end of the show i bought the full oxy-propane setup from Nortel including a hot, new, red Mega Minor torch. On the way home we then stopped off at

Canadian Tire to buy a 5lb bulk propane tank. Woohooo!! No more frozen tanks or piles of 1lb empties!

right side...

Now i love this new torch, i truly do but… one of the less than obvious problems of changing to a new torch is that you have to relearn… everything. Yes, everything: flame chemistry, working areas, sweet spots, colour reactions, etc. After 2.5 years with the Hothead, I was very comfortable with that torch and its quirks so even though it was slow (and noisy!) I could create just about any effect i wanted.

left side...

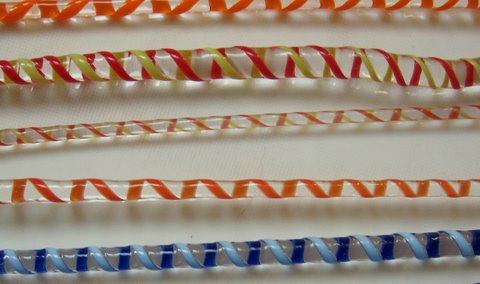

With the Mega, i’m working about 3x faster (wow!),however, after practicing on and off since the beginning of December I’m still not fully able to replicate techniques i easily did on my trusty Hothead. I fell in love with glass colours like turquoise, periwinkle, iris gold, furnace frits and one of the Reichenbach whites based on the beautiful variations they revealed in a reduction (low oxygen) flame. So far, I can’t get any of those colours to do squat on the Mega. Oh well, i guess I just have to keep practicing. Now some people will think I’m crazy but to be honest, i really, really miss my Hothead – the noise, the easy setup and simplicity of it – not to mention its fantastic reduction flame.

While the Hothead uses propane/air, the Mega is a propane/oxygen torch (it can also be used with natural gas). Some people use refillable, tanked oxygen, I preferred the easier route of machine-made oxygen, hence my purchase of this 5lpm Devilbiss oxygen concentrator.

These machines are used new in the health care industry, then refurbished and sold to the lampworking industry. Best of all they provide a convenient, unlimited supply of pure oxygen to the torch and can be daisy-chained for more heat – saves me having to worry about hauling, refilling and chaining huge oxygen tanks.

Paul & Leanne (Reids Beads, Ottawa) stopped by in December and helped me to set up the new equipment because despite reading the instruction sheets that came with the torch and concentrator, and calls to the manufacturer, I still wasn’t comfortable that i knew enough to set everything up correctly. It’s good thing too, because once i watched Paul put everything into place, I realized i really didn’t know how all the various parts were supposed to be put together. Whew!

- what my worktable really looks like…

The Mega is a huge increase in heat and when that’s combined with the fact that i’m now able to torch for much longer periods of time, i’ve noticed a definite difference in how I feel after each torch session – enough to tell me my current studio setup is no longer effective. I’ll have to upgrade my safety glasses to Aur-92s and install a proper ventilation system (in progress).

In the meantime I still have a lot more practicing to get myself up to speed on this new torch: practice, practice (and then more) practice…